Is working in the chemical field in your DNA? Educate yourself on the option of working in the chemical field as a mechanical engineer, and maybe you will find a career that is for you!

First, if you’re looking to launch your own blog and start writing articles yourself, no matter what the subject, you can launch your blog with Bluehost for just $3.95/month.

Start creating content and launch your blog with Bluehost.

Mechanical Engineer

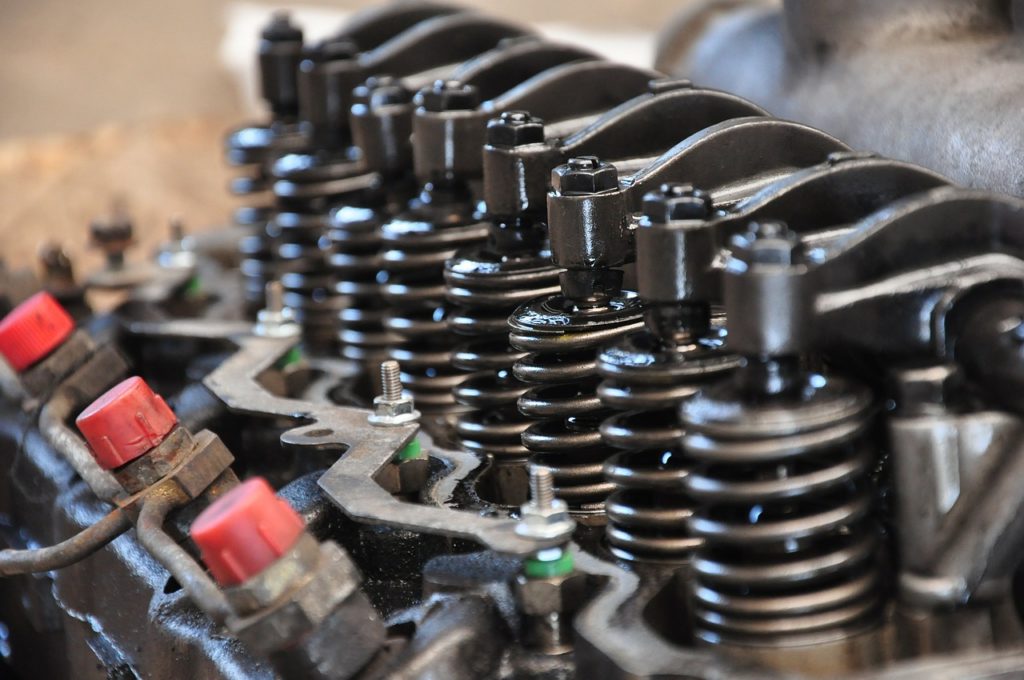

Mechanical engineering is a field related to the analysis, design, testing and manufacturing of objects ranging from children’s toys to airplanes. It is a very diverse field with a large variety of sub-specialties. A mechanical engineer has the skillset to create a concept, design specify each part and then develop that product. These include everyday products such as hair clippers to even aircrafts all these products rely on the skillset mechanical engineer.

The discipline is heavily grounded in physics as mechanical engineers must be experts on the principles that govern forces, motion and energy. Mechanical engineers will be using software tools such as CAD (Computer Aided Design), CAE (Computer Aided Engineering) and CAM (Computer Aided Manufacturing) for most of their workday. Examples of the programs are AutoCAD, Revit, Inventor and Fusion 360. However, mechanical engineers can also occupy their time in laboratories trialing their designs and on the floor of production auditing the manufacturing operations.

Mechanical engineers must possess a strong skillset in physics, computing and math. To gain these skills they may need to utilize math classes through foundation courses and differential equations and sciences such as and calculus-based physics, biology and also chemistry. Individuals looking to be mechanical engineers must earn a minimum of a bachelors degree in mechanical engineering, and may pursue graduate degrees in the field. All states need mechanical engineers to earn a Professional Engineer (PE) license, which requires supervised work experience, education, and many examinations.

Chemical Engineer

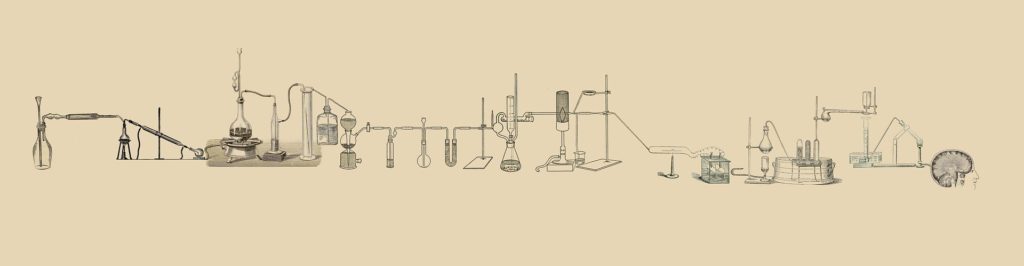

Chemical engineering is the subsidiary of engineering that works with the creation of products through chemical movements and chemical production . This consists of creating systems, equipment and courses for clarifying raw components and for compounding, mixing and refining chemicals to make benificial products.

Chemical engineers utilize the principles of physics, math, biology and chemistry to eliminate issues that come from the production and use of fuel, chemicals, food and drugs and also products, stated by the BLS (Bureau of Labor Statistics). Chemical engineers also rely on Computer Aided Design (CAD) systems to create chemical equipment and plants. CAD systems allow for easy and quick modifications of their designs.

To obtain a job as a chemical engineer, the individual must require the minimum of a bachelors degree in chemical engineering field, however many employers also favors the individual that also holds a state certification as a Professional Engineer (PE). For progression to more senior roles such as management, a masters degree will be required. Additionally, it will be required the the individual partake in ongoing training and education, this is essential to keep up with advances in test equipment, the ever advancing computer software and hardware, technology and government regulations.

Chemical engineers have a background in chemistry, engineering and economics, they utilize concepts from each of these disciplines to eliminate technological problems. Chemical engineers must possess an in-depth understanding of fluid dynamics, mechanical engineering and chemistry. Manufacturing facilities are often extensive, and because of this structural considerations accounted for, and its results and chemical engineers needing to be familiar with and possess skills of structural engineering.

Mechanical & Chemical Engineer Education

Mechanical Engineer

If you are new to the mechanical engineering field, a bachelors degree will be suitable to qualify you for most entry-level jobs. A lot of schools offer majors just in mechanical engineering, or some applicable substitutes include chemistry, math or physics. If you’re interested in entering management or research positions, then you will need a postgraduate degree. You can find several masters and doctoral programs in the same fields, as well as engineering management or business administration.

Within a mechanical engineering program, project management, machine dynamics system modelling, finite element analysis, advanced mechanics and machine systems design will be among the classes you will take. You will also learn by completing engineering projects and completing applied research within the curriculum. An alternative way of learning new skills and furthering your education in the engineering field is to take online courses on platforms like LinkedIn Learning and edX.

Graduate programs include teaching opportunities and research if you are interested in a future career in academia. Additionally, some schools offer online degree programs at both the undergraduate and graduate levels, while other schools offer 5 to 6 year programs where you can complete your bachelors and masters degree at the same time.

Chemical Engineer

Chemical engineering jobs require the individual to possess at least a bachelors degree. Some engineering requirements including extensive labs and chemistry courses, such as organic, physical and analytical chemistry. Chemical engineers must also possess other skillsets such as sequences in physics and calculus. The engineering skillset includes labs and coursework in , reactions, transport and chemical processes.

Students should lean towards degrees accredited by the ABET (Accreditation Board of Engineering and Technology). More than 100 chemical engineering programs have been accredited by ABET. All AET accredited schools follow a certain set of academic rules and educate its scholars a certain set of required industry skills. Most graduate schools and licensing boards require ABET accreditation.

A lot of chemical engineering jobs only require a bachelors degree, some of these positions will look for graduate degrees. Those with more advanced education will be better positioned for management or leadership opportunities. Most schools are for masters and doctoral degree programs in chemical engineering.

It is a requirement in fifty states an engineer that offfers their expertise directly to clients to be licensed. Two exams must be passed to obtain a license. Engineering students that are nearing graduation can undertake the Fundamentals of Engineering (FE) exam. Scholars that then pass the FE exam must gain four years work experience before they undertake the Principles and Practice of Engineering (PE) exam. This is usually the last step in obtaining a licence.

Mechanical & Chemical Engineer Job Description

Mechanical Engineer

Mechanical engineers design, evaluate and manufacture mechanical devices, such as heating and cooling systems, robotics, tools, industrial machinery and transportation systems. Mechanical engineers provide efficient solutions to development of products and processes, ranging from small component designs to extremely large plants, vehicles or machinery. A mechanical engineering occupation include many different factors and also requires skills and knowledge of material computer science, science, and/or physics

Using the principles and knowledge of electronic systems, mechanical structures and the forces of motion, mechanical engineers strive to ensure purpose and quality in all materials. They may work with a group of individuals during the process of manufacturing including other types of engineers, suppliers and machine manufacturers.

Mechanical engineers may work in production operations, technical sales or maintenance, and many are managers or administrators. Approximately 277,500 mechanical engineers are employed in the United States.

Job responsibilities of a mechanical engineer include:

- Estimating time scopes and budgets for each project

- Collaborating with other engineers and project managers

- Analyzing deficiencies or problems and developing solutions to resolve them

- Designing, manufacturing and installing components that fulfill requirements

- Evaluate final product overall performance, safety and reliability

- Test and evaluate theoretical designs

Chemical Engineer

Chemical engineers use both engineering and scientific principles to investigate, design and create chemicals, food, fuel, drugs and a wide variety of other items. They analyze and develop safety measures for those that work with hazardous chemicals and monitor the outcomes through production and conduct tests.

Usually specialization in a specific process such as oxidation is the norm for chemical engineers, or specialization in a particular product or field. Chemical engineers are required to be able to investigate and solve issues as they arise and assess the engineering process for environmental regulations and safety compliance.

A chemical engineer usually works in biotechnology, manufacturing or healthcare. Their job responsibilities will include looking for original methods of developing chemicals, putting together estimates of the production cost and making sure safety procedures are followed for employees working with potentially hazardous chemicals.

Job responsibilities of a chemical engineer include:

- Conduct investigations to develop and advance manufacturing processes

- Create new safety measures for those working alongside potentially hazardous chemicals

- Plan and create the layout of equipment

- Investigate and solve problems that arise with manufacturing processes

- Measure production costs

- Test and monitor the performance of processes throughout production

Mechanical Engineer in the Chemical Field

A mechanical engineer in the chemical field is involved in creating products. The products that they will create differ from mechanical engineering as chemical engineering concentrate on the equipment used to process and produce a range of products. They will often work with dangerous substances, however this may result in them earning a higher salary than regular mechanical engineers.

A mechanical engineer in the chemical field will concentrate/focus on the manufacturing process itself. Contrary to mechanical engineering, they will be involved in establishing safety standards and production methods for the production of their creations. A common employer of a mechanical engineer in the chemical field will focus on petroleum production or chemical manufacturing.

They do not need a Professional Engineer (PE) license to enter the chemical field, however if they are interested in advancement opportunities this may be an option. A mechanical engineer in the chemical field will spend most of their time working indoors in a lab or office, however they may also need to travel as part of their work.

Job responsibilities of a mechanical engineer in the chemical field include:

- Using CAD (Computer Aided Design) to design production equipment

- Preparing project budgets

- Creating safety protocols

- Evaluating equipment performance and improving the design

- Preparing reports for their employers/customers

- Researching the latest state of the art production methods

Thank you very much for being here – we appreciate you taking the time to read our content. If you have anything to add, please feel free to leave a comment down below, and sign up to our newsletter for more of the same!

You can also follow us on LinkedIn, Facebook, Twitter, and Instagram so you can stay up to date.

She/he will use chemical engineering skill sets as an enabling technology to innovate and develop new technologies/systems/processes in various applications. Thank you for sharing.

Exactly, they will be combining both areas of knowledge (mechanical and chemical) to fulfill a specific role and take advantage of their particular skill set, like you said.

Thanks Aroob!