What is Automotive Engineering?

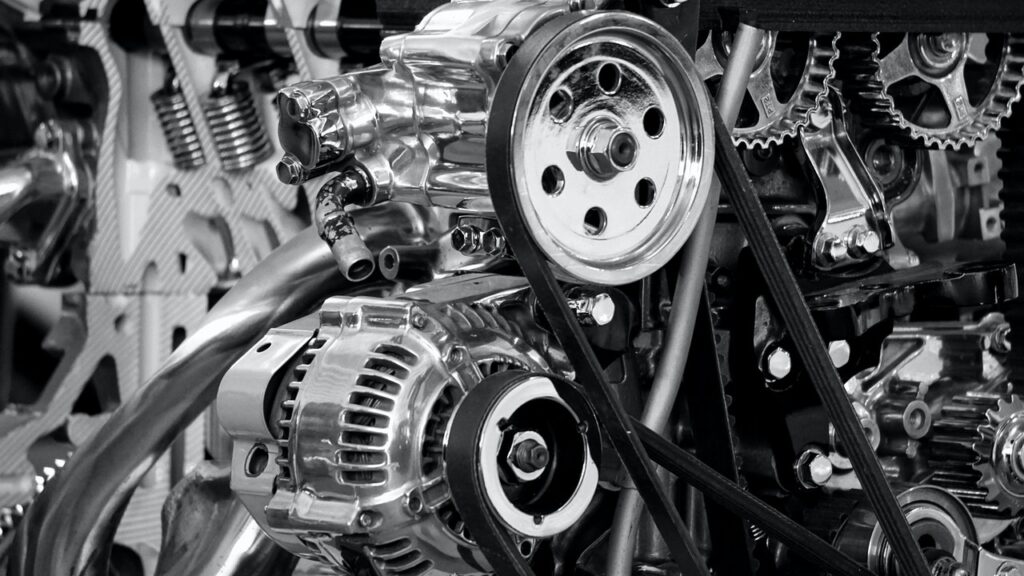

Automotive engineering is the analysis, design, maintenance and manufacturing relating specifically to automobiles, trucks and motorcycles. It incorporates many other disciplines of engineering and can be broken down depending on the engineers area of expertise.

The primary function of an automotive engineer is to look at vehicle safety. This drives all subsequent engineering divisions and procedures. Automotive engineering then incorporates many other fields such as mechanical/structural (design and development of mechanical components), electrical and electronic (looks after the many electronic systems required in a modern vehicle such as lighting, infotainment, Heating Ventilation and Air Conditioning systems etc.) and manufacturing engineers (look after the manufacturing and production of a vehicle to ensure it meets the design intent).

A 4-year degree is the minimum qualification for most automotive engineering positions. Undergraduate programs in this field are most commonly offered in automotive engineering technology, which can cover the basic principles of engineering along with modern vehicle design requirements in terms of fuel economy, safety and industrial manufacturing.

History of Automotive Engineering

It is estimated that over 100,000 patents created the modern automobile. You can point to the many firsts that occurred along the way to producing the modern car. The automobile as we know it was not invented in a single day by a single inventor. The history of automotive engineering reflects an evolution that took place worldwide. However, we can point to the many firsts that occurred along the way. It started with the first theoretical plans for a motor vehicle that had been drawn up by both Leonardo da Vinci and Isaac Newton.

In 1769, the very first self-propelled road vehicle was a military tractor invented by French mechanic and engineer, Nicolas Joseph Cugnot (1725 – 1804). Cugnot used a steam engine to power his vehicle, built under his instructions at the Paris Arsenal by mechanic Brezin. It was used by the French Army to haul artillery at a whopping speed of two-and-a-half mph on only three wheels. The vehicle had to stop every 10 to 15 minutes to build up steam power. The steam engine and boiler were separate from the rest of the vehicle and placed in the front. The following year (1770), Cugnot built a steam-powered tricycle that carried four passengers.

In 1771, Cugnot drove one of his road vehicles into a stone wall, making Cugnot the first person to get into a motor vehicle accident. This was the beginning of bad luck for the inventor. After one of Cugnot’s patrons died and the other was exiled, the money for Cugnot’s road vehicle experiments ended.

Steam engines powered cars by burning fuel that heated water in a boiler, creating steam that expanded and pushed pistons that turned the crankshaft, which then turned the wheels. During the early history of self-propelled vehicles, both road and railroad vehicles were being developed with steam engines. (Cugnot also designed two steam locomotives with engines that never worked well.) Steam engines added so much weight to a vehicle that they proved a poor design for road vehicles. However, steam engines were very successfully used in locomotives. Historians who accept that early steam-powered road vehicles were automobiles, feel that Nicolas Cugnot was the inventor of the first automobile.

Automotive Engineering Education

High school students aspiring to become automotive engineers should develop a solid foundation in algebra, geometry, trigonometry and pre-calculus, physics and chemistry. These subjects are central to understanding the core concepts of any engineering discipline. Automotive engineering students need effective oral and written communications skills. Therefore, high school students should strive to do well in language arts classes, such as writing and speech. High school students should take available advanced placement or college classes to help prepare them for university engineering coursework and get a head start on building college credits.

A bachelor’s degree in automotive engineering technology is the most common route to this job. The program combines technical and scientific applications to teach you about design, research and manufacturing elements related to industrial, personal, and agricultural vehicles. Course topics include parametric modeling, automotive technology, automotive thermodynamics, performance testing, materials and dynamics, industrial safety and fluid power. A culminating project provides an opportunity for creative design to maximize your talents and skills. Required internships place you in a commercial or industrial setting to apply classroom learning and actualize practical skills.

A master’s degree in automotive engineering is not necessary to work in the field, but such a degree will give students specialized automotive engineering knowledge and skills. Moreover, master’s degree programs offer research opportunities for students. It takes about two years to complete a master’s degree program in automotive engineering.

Automotive Engineering Careers

Automotive engineers work in every area of the industry, such as the look and feel of vehicles, and the safety and security of new forms of transport. While there is, of course, a focus to make cars reach high speeds, the modern day engineer needs to consider future sustainability and wider integration of advancing connected technologies.

Jobs

Automotive engineers also known as mechanical engineers, are projected to grow 9 percent from 2016 to 2026 according to the BLS. This is a little slower than the average for most occupations. The need for design on the next generation of vehicles such as electric cars and vehicle systems will keep the career in demand.

Salaries

The top respondents for the job title automotive engineer are from the companies Ford Motor Company, FCA Corp and General Motors Corporation. Reported salaries are highest at Ford Motor Company where the average pay is $91,280. Other companies that offer high salaries for this role include Chrysler Group LLC., earning around $88,000. FCA Corp pays the lowest at around $85,000. General Motors Corporation also pays on the lower end of the scale, paying $86,302.

An entry-level automotive engineer with less than 1 year experience can expect to earn an average total compensation (includes tips, bonus, and overtime pay) of $66,977. An early career automotive engineer with 1-4 years of experience earns an average total compensation of $75,622. A mid-career automotive engineer with 5-9 years of experience earns an average total compensation of $81,210. An experienced automotive engineer with 10-19 years of experience earns an average total compensation of $91,104. In their late career (20 years and higher), employees earn an average total compensation of $97,452.

What Do Automotive Engineers Do?

An automotive engineer provides expertise and direction related to automotive design and production. The ability to multitask, communicate across cultures and problem solve are critical skills needed to be successful in this position. An automotive engineer has varied tasks in a workday.

Responsibilities

Some job responsibilities of an automotive engineer include:

- Interpreting and analyzing results and data

- Investigating and solving problems, e.g. mechanical failures

- Making improvements to vehicles in response to customer feedback

- Organizing and carrying out tests, e.g. to check whether engines will work in different conditions, such as high temperatures

- Providing technical advice and answering queries from clients

- Sourcing vehicle components and selecting the best materials to use

- Using specialist computer modelling software to produce designs

Skills

A automotive engineer can work in various departments such as production, product engineering, product design, research and development, etc., They should posses the following skills to start a career and thrive in that field:

- Creativity: Automotive engineers are responsible for designing and creating mechanical frameworks for vehicle machinery, so creativity in coming up with these ideas is a valued skill for the dealership to help their sales staff communicate each model to their customers

- Math skills: Engineers have to apply the skills they gain during their education, such as calculus, statistics and other mathematical concepts to help them design and fix problems they encounter in the projects they work on

- Mechanical skills: Understanding of mechanical processes assists automotive engineers in communicating with other engineers to complete projects, such as the developing of necessary test features and the evaluation of why products fail or meet expectations of the staff

- Problem-solving: Engineers must have the ability to solve problems that arise when building and testing vehicles. Their knowledge of engineering principles should enable them to create and design products that solve issues in earlier models

- Organization and time management: Engineers work on multiple projects and juggle tasks based on priority, so learning key habits such as organizing a calendar, working with a project management system and taking quality notes are essential to finishing tasks correctly and on time. Having robust time management skills enhances the possibility of having the creative freedom to focus on the design and technical aspects of the role

Future of Automotive Engineering

Imagine a world where car parts can be 3D-printed at record speeds and entire cars can be manufactured in a mere number of hours. This is just the beginning of what may become the 3D printing revolution in the automotive industry. The current timeline to complete the process of manufacturing a car made entirely by utilizing 3D printing technology could take as little as a month. The bulk of the time is taken up by the design phase, where models are created for each part of the automobile. The actual manufacturing process itself could eventually take as little as a day depending on how many printers are available. After, the parts are printed separately, they are assembled to create a car made entirely of 3D printed parts.

Compared to traditional forms of automotive manufacturing, 3D printing is much less taxing on the environment. For instance, printing out individual parts has many advantages due to the lightweight materials used: not only does this allow for waste reduction as a result of using less material, but the lightweight vehicles also allow for higher fuel efficiency which helps to reduce environmental pollution.

Additionally, 3D printed cars will ultimately lower the cost of automobiles. It starts with the lower cost of manufacturing as compared to the immense capital required to build and maintain a traditional automobile manufacturing plant. This cost is greatly reduced in 3D printed cars, and as technology improves, more and more companies will begin to transition over.

Indeed 3D-printing is growing in popularity and has been increasingly implemented across a range of fields. There are a few auto manufacturers that are currently using 3D printing for constructing certain vehicle parts, which are primarily made out of plastic. The aerospace industry is also exploring 3D printing due to its efficacy in fast prototyping. As engineers continue to pioneer this new manufacturing capability, 3D printing is expected to play a significant role for how products will be made across various industries in the near future.

As the world looks towards an uncertain environmental future, it is important now more than ever to consider viable alternatives to traditionally manufactured cars, which account for roughly 20% of the world’s annual air pollution. With their low production costs, lightweight materials, efficient manufacturing time, energy saving fuel efficiency, and ability to reduce pollution, 3D printed cars such as the ones being made at Divergent 3D are looking to the future of automotive engineering to ensure a better future for the planet and its drivers.

If you have anything to add, please feel free to leave a comment down below, and sign up to our newsletter for more of the same content!