Fascinated with engines and machines of all kinds? Well organised and detail oriented? A mechanical engineering technician career involves working with machines in many different ways.

First, if you’re looking to launch your own blog and start writing articles yourself, no matter what the subject, you can launch your blog with Bluehost for just $3.95/month.

Start creating content and launch your blog with Bluehost.

A mechanical engineering technician career includes helping design new products, to creating prototypes and then analyzing them, to manufacturing the finished product which could be machinery parts and equipment, and also operating finished machines.

Job Description

Mechanical engineering technicians troubleshoot design problems, create flowcharts, prepare drawings, take accurate measurements, oversee production lines, perform quality control testing, analyse data and create reports.

From simple routine tasks under close supervision they can progess onto more challenging jobs with less supervision. Employers prefer an associates degree in mechanical engineering or a certificate in mechanical engineering technology, some have been known to accept a high school graduate with science and math courses or some additional vocational training.

Mechanical engineering technicians can also advance in responsibility and earn a four year degree that will take them even further.

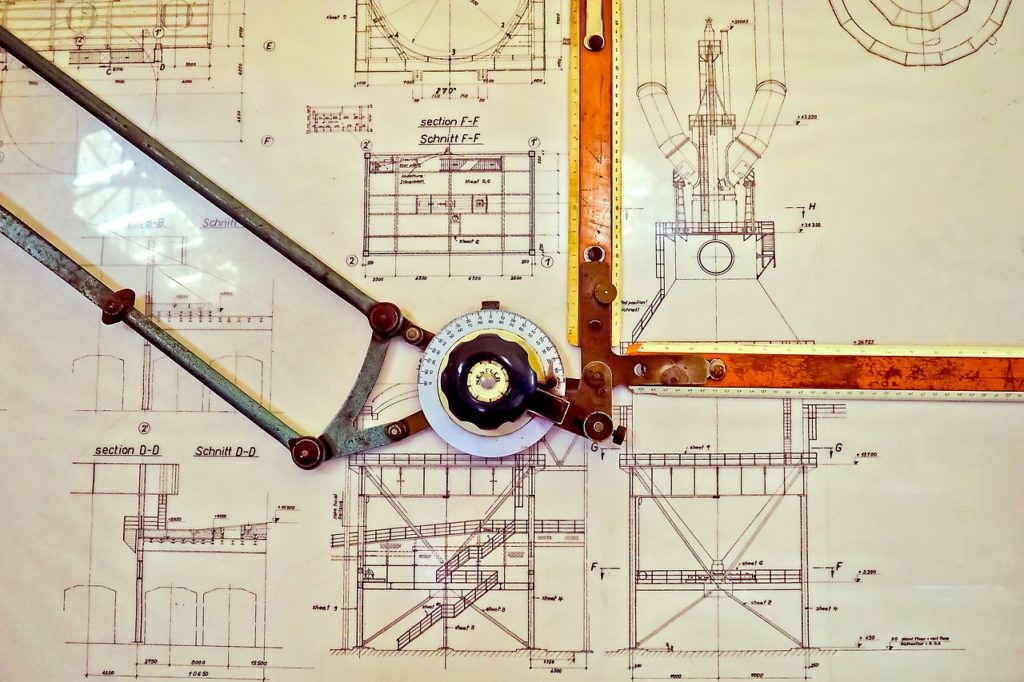

They are usually instructed by mechanical engineers, these technicians avail of 3-D CAD (Computer Aided Design) software like AutoCAD, Revit, Inventor and Fusion 360. Sometimes they even use paper and pencil to create sketches/models of products to be developed. They also sketch up the process for assembling these parts together.

Based on their designs, they plan and produce new mechanical parts or make changes to existing products. Precision is critical, products and equipment are rigorously tested and the results are compared with original design specifications.

To aid in determining the viability of creating parts, a mechanical engineering technician estimates the cost of labor, the equipment lifespan, and the plant space needed for production.

Towards the end of a project you inevitably get involved in programming and software, so you will gain experience of the electrical aspect of a mechanical engineering project as well.

Workplace

When problems are found, mechanical engineering technicians work alongside engineers to eliminate production issues. These technicians generally work for manufacturing facilities and engineering firms on products such as control panels, flight simulators and research labs.

Most mechanical engineering technicians work 40 hours a week in a laboratory office, industrial plant or at a construction site. A mechanical engineering technician career does not consist of sitting behind a desk from 9 to 5 that is for sure!

Mechanical engineering technicians need a good understanding of all manufacturing processes including but not limited to welding. A technician in this field would oversee the entire design and manufacturing process to ensure the work is done to specification and to a high standard.

Some qualities that can make someone a good mechanical engineering technician are;

- You need to be practically minded

- You work well in a team environment

- Your problem-solving skills are very important

- You need to be able to come up with a solution while working through a problem

Mechanical Engineering Technician Career

A common path to becoming a mechanical engineering technician is studying engineering as a subject while in high school. You can then move on to complete a mechanical engineering apprenticeship, and further on to study a degree in mechanical engineering or an equivalent. This will give you the necessary design, mathematical and programming skills to qualify for a mechanical engineering technician role. One’s skills can always be improved regularly by taking courses online on LinkedIn Learning, where certifications can be earned and therefore increasing a mechanical engineering technician’s employment chances.

Mechanical engineering can be found to be very rewarding, an idea is taken from a customer or an idea that has been worked on with a customer. A solution is designed – typically involving the design and build of equipment, this equipment is then installed and it can be seen running and hopefully solving the initial problem.

This is essentially taking an idea and bringing it to reality.

There will always be a need for mechanical engineering, almost every industry needs mechanical engineering and therefore mechanical engineering technicians. It is a very solid career choice, it is always evolving and there are always new challenges around the corner. You should hopefully never get bored!

Example of the Mechanical Engineering Technicians Workflow (Shaft & Sprocket)

Mechanical engineering starts off with a design, then moves on to the measurement, then the manufacturing process of the parts which takes place in the workshop. Next comes the assembling machinery which assembles the parts, and then installation and commissioning on site.

Before a mechanical engineering technician can complete any work they will need to don the appropriate safety gear and follow any safety rules or regulations in the workshop.

Design

A mechanical engineering technician will typically have the CAD drawing of the desired design in hand when they walk into the workshop.

A CAD drawing could be made of a shaft and sprocket component for a box folding machine, by designing a couple of sprockets, bearings and other components. These CAD drawings will then be brought to the appropriate machines to manufacture the part itself, and transform the measurements into cold hard steel.

Measurement

Using a Vernier Calipers the steel will be measured, and the length of steel specified on the drawing will be cut using a band saw.

Manufacturing

After cutting the part to the right length using the band saw, you can give it a quick wipe down, before putting the part into a lathe.

The center lathe will refine the core steel to within a 100th of a millimeter of its measurement and it will start to resemble the desired sprocket and shaft.

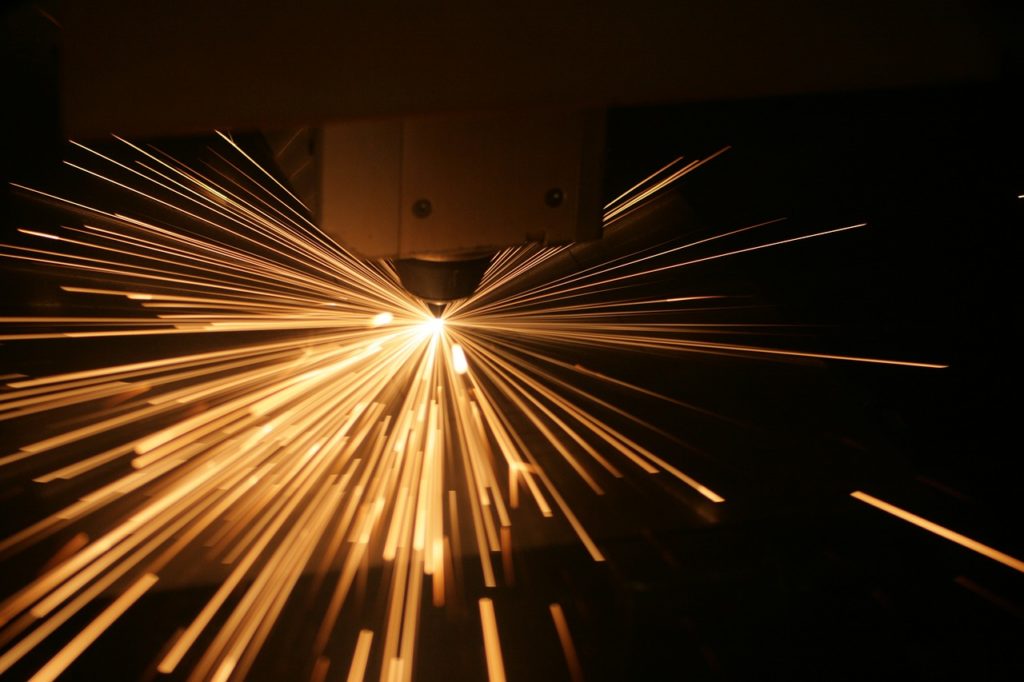

Laser Cutting

Such a part like the sprocket and shaft will need to be laser cut off site, the laser cutting process is really one of the processes that have revolutionized the way that a mechanical engineering technician works.

Laser cutting is a precision cutting edge technology used to finally cut metal materials. The high-powered beam of laser is directed onto the metal via a computer leaving an edge with a smooth, high quality surface area. It is really fast and cost-effective way of making components.

Once the sprocket and shaft part is received back from the laser cutting company, it is ready to be installed.

Installation

It is now the moment of truth where it can be seen how accurate the measurements, manufacturing and designing of the part has been. In this case the machine will be started to ensure that the part works as expected.

List of Mechanical Engineering Technician Duties

- Evaluate design drawings for new or modified tools, measuring dimensions on drawings and comparing them with the original design

- Prepare drawings and layouts of parts to be made and of the process for putting them together

- Discussing changes in the design of the part, in the way it will be made, put together and the techniques and processes that will be used

- Conducting tests of complete units and parts as they would normally be used, this is to investigate proposals for improving equipment performance

- Record test results and procedures, graphical and numerical data, plus recommendations for changes in test methods or the products themselves

- Compare the original design specification and test objectives to the test results

Thank you very much for being here – we appreciate you taking the time to read our content. If you have anything to add, please feel free to leave a comment down below, and sign up to our newsletter for more of the same!

You can also follow us on LinkedIn, Facebook, Twitter, and Instagram so you can stay up to date.