Fusion 360 is becoming one of the most used Computer Aided Design (CAD) tools on the market for casual users (hobbyists), because of its unique features. It is a single cloud-based, collaborative platform for engineering, CAM and design and has similar functionality to Inventor, SolidWorks or Catia. It allows the user to carry out their entire product design and development process on one (cloud-based) program.

Fusion 360 is a CAD program developed by Autodesk, one of, if not the biggest companies in the computer aided design industry. They have also created the household names AutoCAD, Inventor and Revit that are used by millions of professionals. They are exploring a new avenue with their latest product, Fusion 360, which is a tool aimed towards hobbyists, or casual users.

This program has grown in popularity especially in the 3D printing field. Before we go through what Fusion 360 is exactly used for, lets learn a bit about its history and how this useful tool for hobbyist CAD users came about.

History of Fusion 360

Inventor Fusion 360 was released in June 2013, and began its existence as a direct modeler to fill a void in Autodesk’s software line that they did not yet have a good solution for. A few years passed and it was evident that the way that Fusion 360 utilized cloud storage and capability needed to be expanded on and developed further.

Parametric modeling was introduced to the program and their strategy changed along with its name from Inventor Fusion 360 to just Fusion 360. Now well into its seventh year, and the product has came a long way from its humble beginnings. It is still evolving at a good pace and has added functionalities like Computer Aided Manufacturing (CAM) and drawing support, simulation and the consistent development of its cloud technology.

What is Fusion 360 Used For?

Cloud-Based

Fusion 360 is a cloud-based modelling tools, as you should know by now. When a model that is being worked on is saved, it is not being saved locally on that particular device but on a server. The project can be exported onto a hard drive if it is needed offline, and this is also a method of converting a models files into the OBJ and STL file formats.

Being based on the cloud, this also means that one’s models and projects can be viewed online form any computer/device. Mobile apps are available on both Android and iOS to allow users a more portable and remote way of reviewing models on the go, which in turn promotes better team collaboration.

This negates a lot of the hassle of team collaboration on bigger projects where design decisions, markups and comments are being shared constantly. It does not matter what device you are viewing Fusion 360 on, what version you have of the program or what file type you prefer to use. All of this information is containing within Fusion 360 and it also makes it easy to share files with a click of its “Share Public Link” button. This ease of sharing is unheard of in 3D CAD applications.

Manufacture

CAM is natively supported in Fusion 360, this essentially allows your CAM design to be produced physically on a Computer Numerical Control (CNC) machine. It features tools to make cuts, using the software’s default tools or you can manually enter the attributes and specs of a tool that you won already. It also uses an Adaptive Clearing technique, which allows for large sections of material to be cleared.

Once a toolpath is generated, you can see the simulation of the creation of the model, and analyze the cutting process. This leads to problems in the cut being avoided or any last minute design changes can be made before any actual machining takes place. This efficiency can save a lot of money and time, as it reduces wear on machines and tools, and prevents errors in design.

Part Modelling

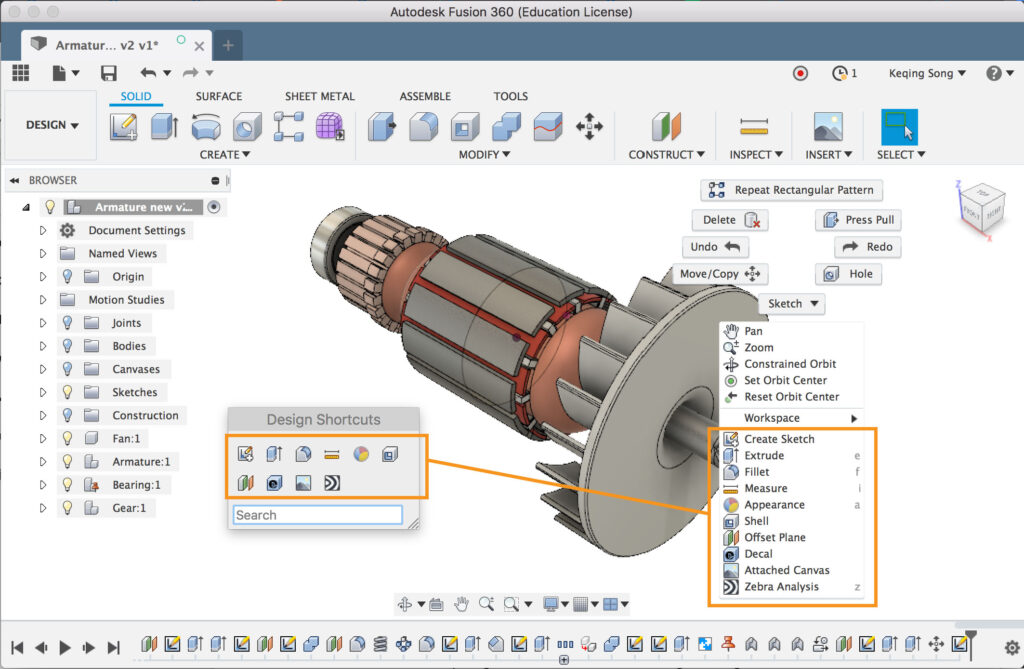

Fusion 360 incorporates multiple different working environments, with each one possessing different options and features. When you first open the program, a blank modeling plane is presented as the Design environment is the default option.

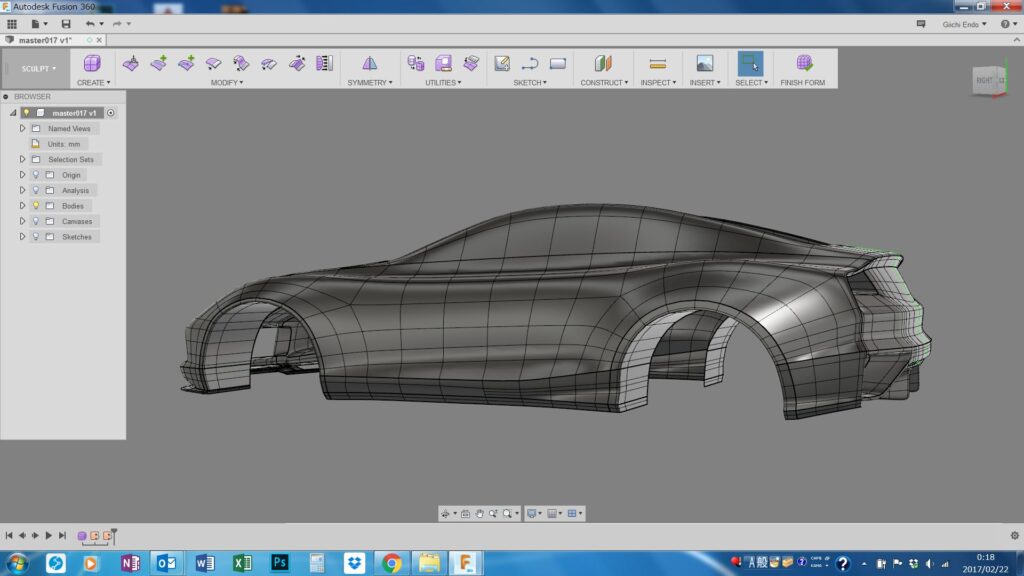

3D modeling is then created within this environment, and the amazing parts about Fusion 360 is that you have the convenience of having direct, parametric, freeform and surface modeling all in the one place. While modeling in one space it is a click of a button to transfer from lets say a freeform workspace to parametric. This is one of Fusion 360’s biggest time saving features.

Rendering

When a design is created on any computer program, there is always a desire to know what it would look like in the real world as an actual product. The Rendering feature within Fusion 360 creates a real-world environment tailored to your exact desires, and shows the selected model in a realistic view.

The user can add material attributes to the surfaces, like wood, marble, metal, glass among many more. Certain plug-ins like KeyShot can be downloaded to produce an even more realistic final render.

Simulation

When virtually testing a design, simulation can be essential to analyze how the design reacts based on forces and external pressures applied to it. Simulation can show if a model is unbalanced, how it performs in real-life situations and if it will fail under certain loads or stresses. A list of some of the variables that can be changed within Fusion 360 are:

- Modal frequencies

- Static stress

- Temperatures

- Structural buckling

- Non-linear static stress

- Thermal stress

This can be tricky for non-experienced users, but when used properly is can be a useful tool in the design process.

Who Uses Fusion 360?

It is used by mechanical engineers and designers in many different fields and industries. Some of the companies that use this program are: ModBot, Lockheed Martin, Snack Crate Inc., RJ Watson Inc., Orange County Choppers among many more.

Fusion 360 Prices & Licensing

If you are a newbie to the 3D CAD modeling industry, then Fusion 360 might just be the place to start your journey. It is suited to students, entrepreneurs and hobbyists as Autodesk offers a FREE license if you qualify for certain criteria:

- If you run a hobby business and the business does not make more than $100,000 every year

- If you are an educator or a student, in this case you can get a three-year subscription

- If you are only using it for personal projects outside of a business

If the above criteria are not met, unfortunately you will not qualify for a free subscription, however there is a paid option for $495 annually or $60 per month.

Do you have any experience with Fusion 360? If you have anything to add we would love to hear about it! Let us know with a comment down below and sign up to our newsletter for more of the same!

Thank you very much for being here – we appreciate you taking the time to read our content. You can also follow us on LinkedIn, Facebook, Twitter, and Instagram so you can stay up to date.