What does a mechanical engineer typical day look like? Read below to find out!

First, if you’re looking to launch your own blog and start writing articles yourself, no matter what the subject, you can launch your blog with Bluehost for just $3.95/month.

Start creating content and launch your blog with Bluehost.

Mechanical engineering is one of the broadest engineering fields. A mechanical engineer typical day would include designing, researching, building, developing and testing mechanical devices and systems, including engines, machines, tools, sensors and devices.

Some may say that there is no “typical day” for a mechanical engineer, we will do our best to describe the relevant duties and responsibilities of a mechanical engineer in their day-to-day life.

General

About half of today’s mechanical engineers have a primary focus on design engineering, with three-quarters doing some work in the area, with the use of programs like AutoCAD, Revit, Inventor and Fusion 360 being prevalent in the industry. Plant Equipment, System and Product Design are all forms of design engineering.

Engineering projects are usually multi-disciplinary organizational efforts and involve working with different people in various engineering disciplines and professions.

Communication is key and the solution to any problem that may arise could include learning new skills or gaining experience in another field, this can also then help to develop some career options down the line that may not have been apparent when the job was first taken.

First Job

Some entry-level mechanical engineers end up being surprised by the responsibilities that go with their first job. It is expected that you learn on the job and you can grow and improve on all aspects of your career as you progress.

On the other hand, you will not be expected to go this road alone, managers, supervisors and members of your team will be on hand to help you along the way with any problem that you encounter.

No matter how well you did in school or college, your curriculum in mechanical engineering is only an introduction into the world and ways of engineering. It will never be as easy as just applying a formula or some theory to a problem. Your previous education and experience will have to be drawn on and you will have to routinely learn new things to solve a problem.

This is one of the many challenges that comes with a career in mechanical engineering, however it is a great source of satisfaction as you move forward. One way to deal with these challenges is to constantly hone your skills and improve, this can be achieved on a platform like LinkedIn Learning, which provides courses to improve an engineers knowledge in an array of areas.

Field Work

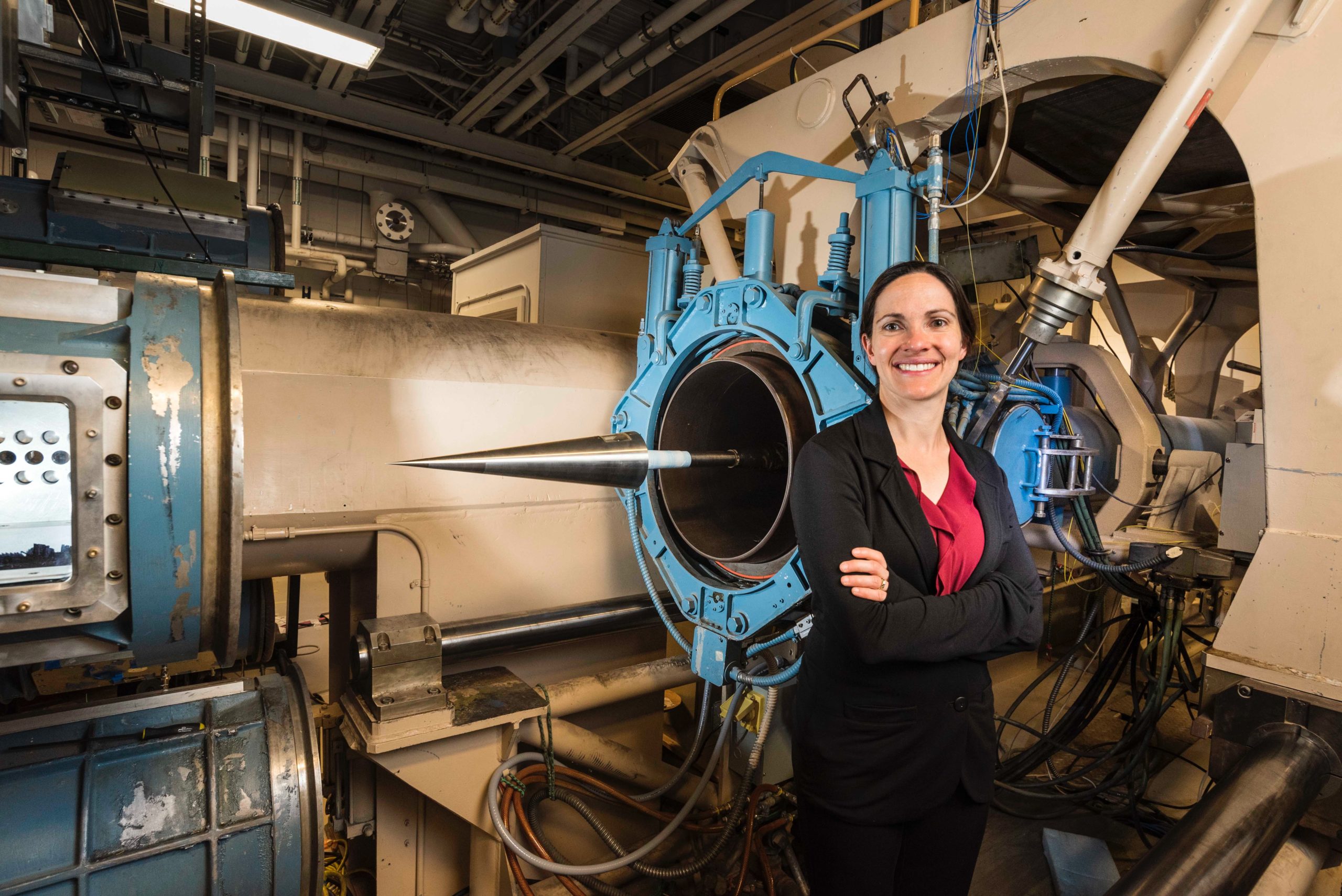

Typically mechanical engineers carry out laboratory testing and field work earlier in their careers as opposed to more experienced engineers.

Computer simulation technologies have dramatically affected the way that physical testing is carried out in the field. Advancements in this field have lessened the amount of testing that is physically done on site.

Data gathered is used more for the supplying of information to CAD (Computer Aided Design) tools and these software programs are then used to simulate simple to very complex “real world” problems.

Business

Business and mechanical engineering are very closely linked. The products and services produced by mechanical engineers are driven by customer needs and cost objectives defined by management.

Mechanical engineers work with and advise the financial marketing managers on the feasibility of new projects, when approved, they then design and build the production facilities.

What is sometimes underestimated is the thousands of engineering service companies, a lot of which are large companies. This makes business and management occupations a major career option for mechanical engineers.

Duties

While I wont go into a detailed mechanical engineer job description here, we will go through a quick rundown of what a mechanical engineer typical day looks like.

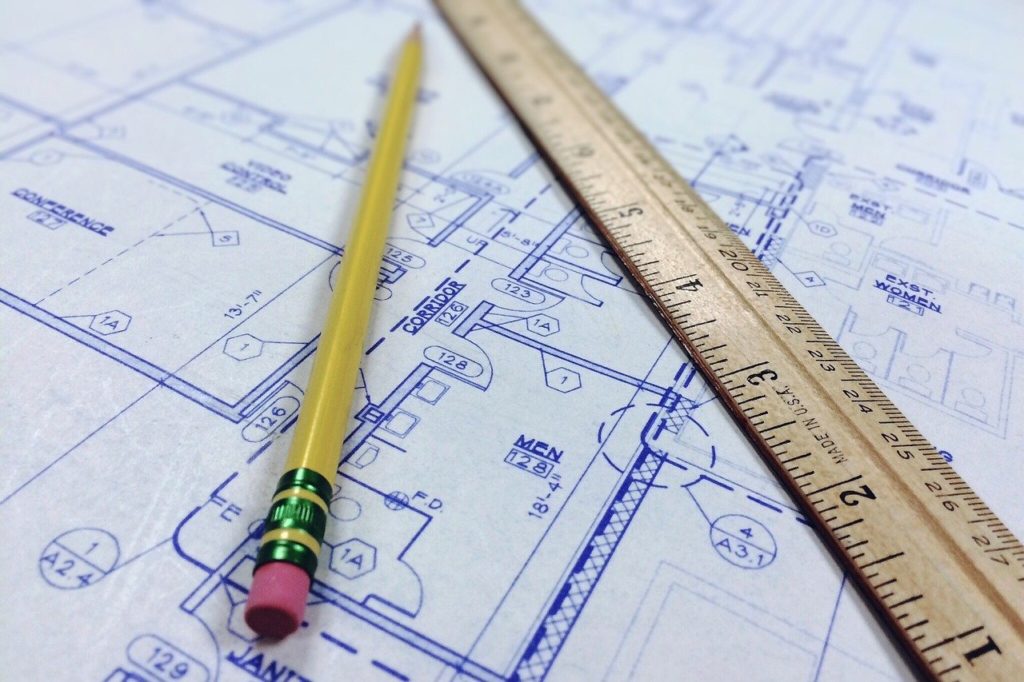

Mechanical engineers on a daily basis read and interpret technical drawings, computer-generated reports, blueprints and schematics. They discuss these with other engineers or team members from different professions to resolve system malfunctions, provide technical information or implement operating procedures.

As mentioned previously, one of mechanical engineers’ main responsibilities are to research, design, evaluate, install, operate or maintain mechanical devices, equipment, systems or processes to meet certain requirements.

They can also specify direct modification of products or system components to ensure that the product meets the performance, design and environmental scope.

Mechanical engineers also fulfill a lot of management roles and therefore have to perform personnel functions, such as supervision of technicians, technologists, production workers and/or other engineers.

A mechanical engineer typical day could look a bit like this:

- Look over blueprints/schematics to plan the work needed to be completed for a project

- Review these technical documents with team members to resolve any design issues or operational problems

- Work with or supervise technical personnel to create the new designs and/or plans

- Evaluate the specifications and characteristics of the systems or equipment and change the design as needed

- Oversee the manufacturing process

Industries

Of course, a mechanical engineer typical day does change depending on where they might work. The various careers that a mechanical engineer can work towards, as their abilities are so diverse, will lead to one engineer’s “typical day” looking a lot different than the next.

The following are examples of the different types of mechanical engineers:

Automotive Research Engineer

Automotive research engineers typically design new products and modify existing ones, troubleshoot and solve engineering problems. They focus on the research and development of buses, trucks, cars, motorcycles or off-road vehicles.

Heating and Cooling Systems Engineers

Heating and cooling systems engineers calculate energy loses for buildings by using tools such as combustion analyzers, computers or pressure gauges. They also design equipment, control apparatus and develop different procedures for testing products.

Materials Engineers

Materials engineers study the structures, mechanical uses and chemical properties of plastics, nano-materials, metals, ceramics and composites according to the place of usage. They achieve this by developing, processing and testing materials in an effort to make new materials that have different specifications and characteristics.

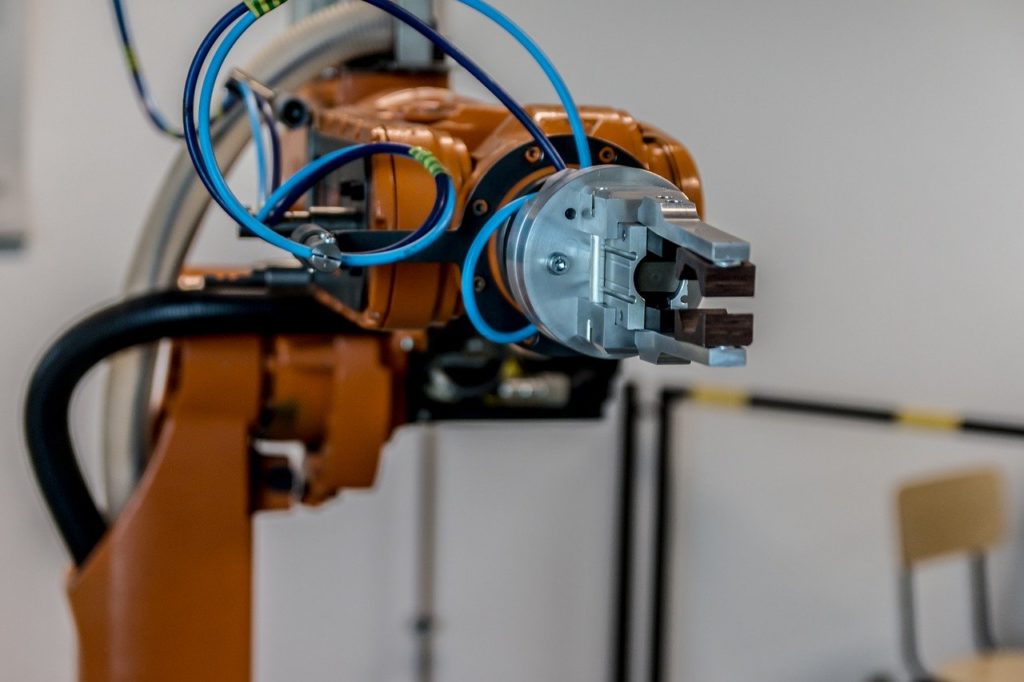

Robotics Engineers

Robotics engineers spend the most of their time designing the plans and creating the designs needed to build robots, while also designing the processes necessary for the robot to run correctly. They are primarily a behind-the-scenes engineer who spends all of their time working on projects and not on-site or dealing with clients etc.

Thank you very much for being here – we appreciate you taking the time to read our content. If you have anything to add, please feel free to leave a comment down below, and sign up to our newsletter for more of the same!

You can also follow us on LinkedIn, Facebook, Twitter, and Instagram so you can stay up to date.

1 thought on “Mechanical Engineer Typical Day”

Pingback: Top 10 typical day of a mechanical engineer That Will Change Your Life - Nhôm kính Nam Phát