CNC machining has quickly become a popular choice for rapid prototyping. In this article, we will explore some of the reasons why CNC machining is often chosen for rapid prototyping. First, we will discuss the benefits of this type of machining over other forms of rapid prototyping. Then, we will explore some factors influencing a decision to use CNC machining for rapid prototyping. Finally, we will examine examples of how CNC machined parts can be used in prototypes.

What is CNC Machining, and What Are its Benefits for Rapid Prototyping?

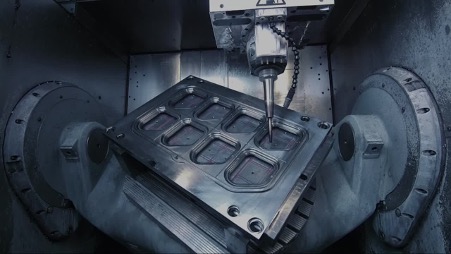

CNC machining uses computer numerical control (CNC) to guide a machine tool to create custom parts from various raw materials. This production method allows for accurate and repeatable manufacturing operations, making it ideal for rapid prototyping. It also offers minimal material waste, as each part is custom-made according to the specifications of your prototype. Furthermore, CNC-machined components are typically more robust and durable than other components used in rapid prototyping due to their greater accuracy and precision.

How Does CNC Machining Work, and What Are the Different Steps Involved in the Process?

CNC machining typically consists of three basic steps: programming, setup, and cutting. The programming step involves creating a custom program for the CNC machine to guide it in creating the desired part. This program is usually created using software specifically designed for this purpose.

The setup involves preparing the CNC machine with the tools, materials, and fixtures needed to execute the custom program accurately. Finally, the cutting step sends the custom program to the CNC machine, which executes it to create custom parts according to your specifications.

What Factors Should You Consider When Deciding to Use CNC Machining for Rapid Prototyping?

It would help if you considered several vital factors when deciding whether or not to use CNC machining for rapid prototyping. The first is the timeline and cost of the project. Machining can be time-consuming, but it also offers greater accuracy and precision than other methods, which may make it worth the investment if you need custom parts quickly. Additionally, it would help if you considered whether or not the material you’re using is compatible with CNC machining and whether or not your design can be accurately replicated with CNC technology.

What Are Some Examples of How Custom CNC Machined Components Can Be Used in Prototypes?

Custom CNC machined components can be used in prototypes to create custom fixtures, housings, enclosures, mechanical parts, connectors, brackets, and more. For example, custom housings can be machined to hold custom electrical components, and custom enclosures can contain custom circuit boards. Additionally, custom mechanical parts such as gears and levers can be machined with precise tolerances for a functional prototype.

What Materials Can Be Used with CNC Machining to Create Rapid Prototypes?

CNC machining can be used with various materials, including aluminium, brass, steel, stainless steel, titanium, and plastics. Each material has unique properties that make it suitable for different applications. For example, aluminium is a lightweight and robust material often used for custom enclosures or custom connectors in rapid prototypes. Steel is a solid and durable metal perfect for custom brackets or mechanical parts in prototyping applications.

What are Some Challenges Associated with CNC Machining for Rapid Prototyping, and How Can They Be Overcome?

One of the main challenges associated with using CNC machining for rapid prototyping is that it can be time-consuming. It’s vital to ensure you have a custom program ready to send to your CNC machine before beginning the process. Additionally, ensuring you have access to compatible materials and fixtures is vital, as these are necessary to create custom components accurately.

Finally, custom CNC machining requires experienced technicians who understand the intricacies of programming and operating the machines. By utilizing experienced personnel, custom parts can be quickly created with greater accuracy and precision.

How Has CNC Machining Changed the Way Products are Developed and Brought to Market, and What Impact Has It Had on Businesses?

CNC machining has had a significant impact on the way products are developed and brought to market. It has allowed custom components to be quickly created with greater accuracy and precision than ever before, enabling businesses to bring better products to market faster. Additionally, it has enabled businesses to reduce their development costs while maintaining high quality and performance levels in their end products.

Finally, it has allowed businesses to create custom parts that weren’t possible before, allowing them to differentiate themselves from their competitors. Overall, this has helped businesses develop better products more efficiently and cost-effectively, which has helped them grow and succeed in today’s competitive markets.

In conclusion

CNC machining has revolutionized the way prototypes are created, allowing businesses to develop better products faster and cost-effectively. With careful consideration of materials, design features, and processes, businesses can use custom CNC machined components in their prototypes to create high-quality solutions that meet their customers’ needs. By leveraging the capabilities of CNC machining for rapid prototyping, businesses can bring innovative products to market faster and stay ahead of their competition.

Thank you very much for being here – we appreciate you taking the time to read our content. If you have any other tips you would like to add, or if you have used any tactics previously that worked well, please let us know with a comment below!

You can also follow us on LinkedIn, Facebook, Twitter, and Instagram so you can stay up to date.